Interview conducted with Sibel Ergünes and Histotechnician Camilla Grandal, at Odense University Hospital in Denmark.

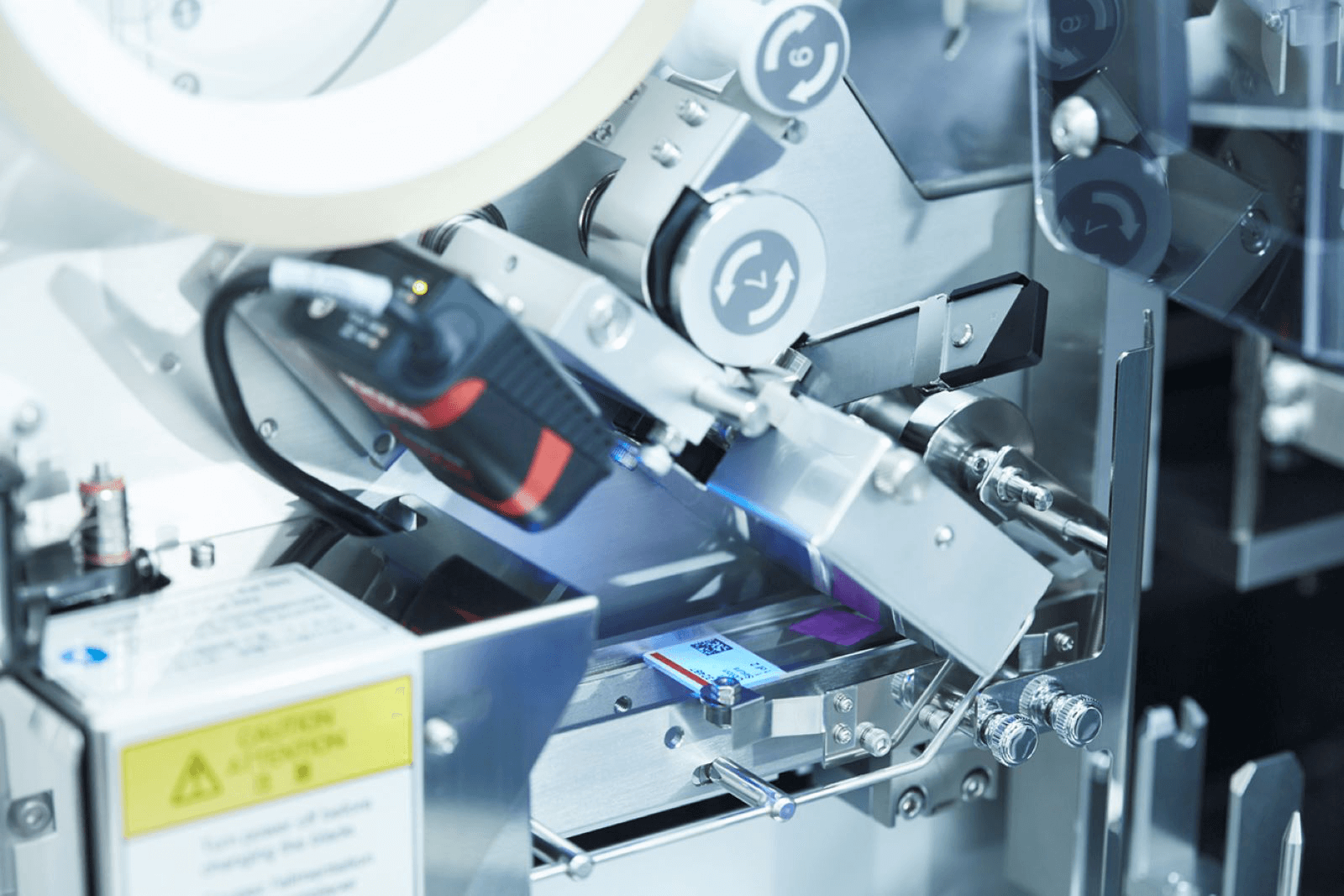

Moving to the latest technology platform, the Tissue-Tek AutoTEC® a120

Odense University Hospital (OUH) in Denmark is the largest hospital in the region of South Denmark. It has 1,045 beds spread over all medical specialties and the staff includes approximately 11,000 employees.

Sakura® spoke with Sibel Ergünes and Camilla Grandal, both super users from the Pathology Department, to learn from their experiences with the new Tissue-Tek AutoTEC a120.

Why did you invest in a Tissue-Tek AutoTEC a120?

Ergünes explains that during the past 5-7 years they have had an increasing workload, where the contributing factors were the rising incidence of cancer within the aging population, both resulting in increased tests to be performed.

We also wanted to change the workflow in the lab to prepare for the future and realised that our current Tissue-Tek AutoTEC® was not able to fulfil our needs. Therefore management made a decision to purchase an additional automated embedding machine.

Grandal adds that automation made it possible to free up labour for other purposes.

What is important to you, in regard to the performance of the Tissue-Tek AutoTEC a120?

The most important thing is of course the quality of the blocks. They have to be as high in standard as with the old Tissue-Tek AutoTEC. Other parameters include the ease of use, the maintenance we have to carry out and the reliability. Let me try to explain it in more depth.

Time saving

One of the main reasons of going from manual to automated embedding, was the time saved. Before the Tissue-Tek AutoTEC arrived back in 2010, we had four to five people occupied at embedding stations from the morning up until lunch. Now we have one to two people embedding for 1-2 hours, so we have gained resources to be used elsewhere in the lab.

All the routine work has been automated and we can spend time on more challenging things, which require our histology skills. Compared to Tissue-Tek AutoTEC, the Tissue-Tek AutoTEC a120 has a variable warm-up time, which is really appreciated. We can start almost directly without waiting 15 minutes for the instrument to get ready.

Ease of use

One thing that is really important for us as histotechnicians is that our instruments are easy to use.

Remember we have a lot of different instruments in our labs, so the more intuitive the graphic user interface is, the easier it is for us to do the operations. You can almost compare the Tissue-Tek AutoTEC a120 with an iPhone, the screen tells you exactly what to do and as the size of the screen increases it becomes even easier.

The fact of being able to see the recovery zone of the rejected blocks is an advantage. In effect, this eliminates the risk of forgetting these cassettes. The arrival time of the embedded blocks is also indicated, making the workflow easier.

Ergonomics

One of the major improvements with the Tissue-Tek AutoTEC a120 is that you can access all necessarily functions from the front, meaning it can be placed directly against the wall and not in the middle of the lab. The refilling of paraffin takes place at an elbow level and not top filled as with the Tissue-Tek AutoTEC predecessor. The magazines slide in easily and the opening mechanism is so much quicker. This impacts our ergonomics as we do it several times each day. The maintenance tools have a location of their own in the system, meaning we avoid scattering and wasting time finding them. Stejlsted, a histotechnician highlights that, “It’s so intuitive and easy to operate - even without training”.

Maintenance

This is another important factor for us. With several different instruments at the lab, the time we spend on maintenance has to be as little as possible, without sacrificing the quality of the specimen.

The Tissue-Tek AutoTEC a120 really has made improve-ments. Drip trays and checking paraffin level is what we do every day, the rest is on a monthly basis.

Quality of blocks

Sakura was curious to the viewpoint of the pathologists on the Tissue-Tek AutoTEC a120, and whether we would get the same high quality as before. A blind test was carried out and the result was, according to Bak Jylling (a pathologist), “Top quality – [with] absolutely no difference”.

Results:

- Tissue-Tek AutoTEC a120 is faster than its predecessor.

- Blocks are ready earlier, allowing for workflow optimisation.

- Tissue-Tek AutoTEC a120 requires minimal maintenance.

End note

Grandal highlights that it’s very common in Scandinavia to name your equipment in the laboratory after famous movie stars, kings or queens, even popular pet names have been used and of course our new instrument had to have a name. The old Tissue-Tek AutoTEC is named Oscar and we had to decide whether or not Oscar should have a boyfriend or a girlfriend. So competition was arranged and the winning name was Hugo (a very popular cartoon hero for smaller children).

“All the routine work has been automated and we can spend time on more challenging things, which require our histology skills. ” (Sibel Ergünes and Camilla Grandal)

Department of pathology of Odense University Hospital in Denmark

In mid-2017, the Institute had a staff of approximately 145 people. This consisted of:

91 Histotechnicians

10 Secretaries

3 Molecular biologists

35 Doctors3 Professors

17 Senior physicians6 Department physicians

9 Residents

The workload has steadily increased with an average of 5% each year since 2010. Today, the total number of pathology reports is 84,130, where histology reports accounts of 58,700. The yearly production of glass slides is 430,000, which includes IHC and SS as well.

The department of clinical pathology at OUH, the first site in Europe equipped with a Tissue-Tek AutoTEC a120 as well as its predecessor, produces between 500-1200 blocks a day, meaning that more than 120,000 blocks are embedded automatically each year.